US 300 Medium Capacity Ultrasonic Washer

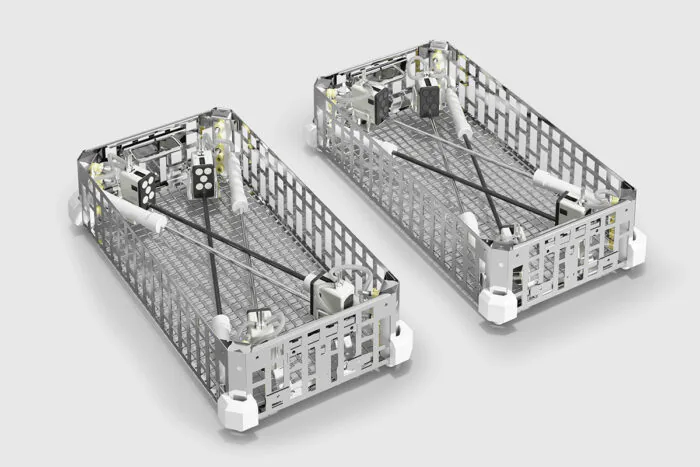

Our US 300 is equipped as standard with a removable washing basket, allowing loading and connecting instruments on a separate workbench. Ported instruments are directly connected through standard luer lock connectors. The connection of non-ported instruments is made by the use of injection sleeves with silicone seals.

Key Features

-

High Productivity

Ultrasonic washing of up to 40 hollow instruments in a single cycle

-

Design and Safety

High-quality stainless steel AISI 316L washing tank and stainless steel AISI 304 external body for long-term reliability and cleanliness

-

Complete Reprocessing Cycle

In one device, ultrasonic treatment, thermo-disinfection, and drying

-

Hands-Free

Automatic lid opening, closing, and cycle start option via Infra-Red Proximity Switch, avoiding operator physical contact.

-

User Friendly Large HMI

User-friendly soft-touch glass control panel with 4.3″ graphic colour LCD display, allowing for 40 programming options.

-

Traceability

Port for printer connection and USB port for cycle data download. Data traceability with SteelcoData software.

Certifications

- Steelco Ultrasonic washers are designed and constructed to comply with the latest European guidelines on decontamination EN ISO 15883-1/2, CEN ISO/TS 15883- 5, and classified CE Medical Device (Community rule 93/42/CEE) code nr. 0051.

Configurations

Dimensions WxDxH (mm) | Basket Dimensions | Enquire |

|---|---|---|

| 890 x 675 x 1045 | 700 x 350 x 150 |

Downloads

Steelco Ultrasonic Washers

Download

Thank you for requesting a quote. A member of our team will be in touch shortly.

Thank you for requesting a quote. A member of our team will be in touch shortly.