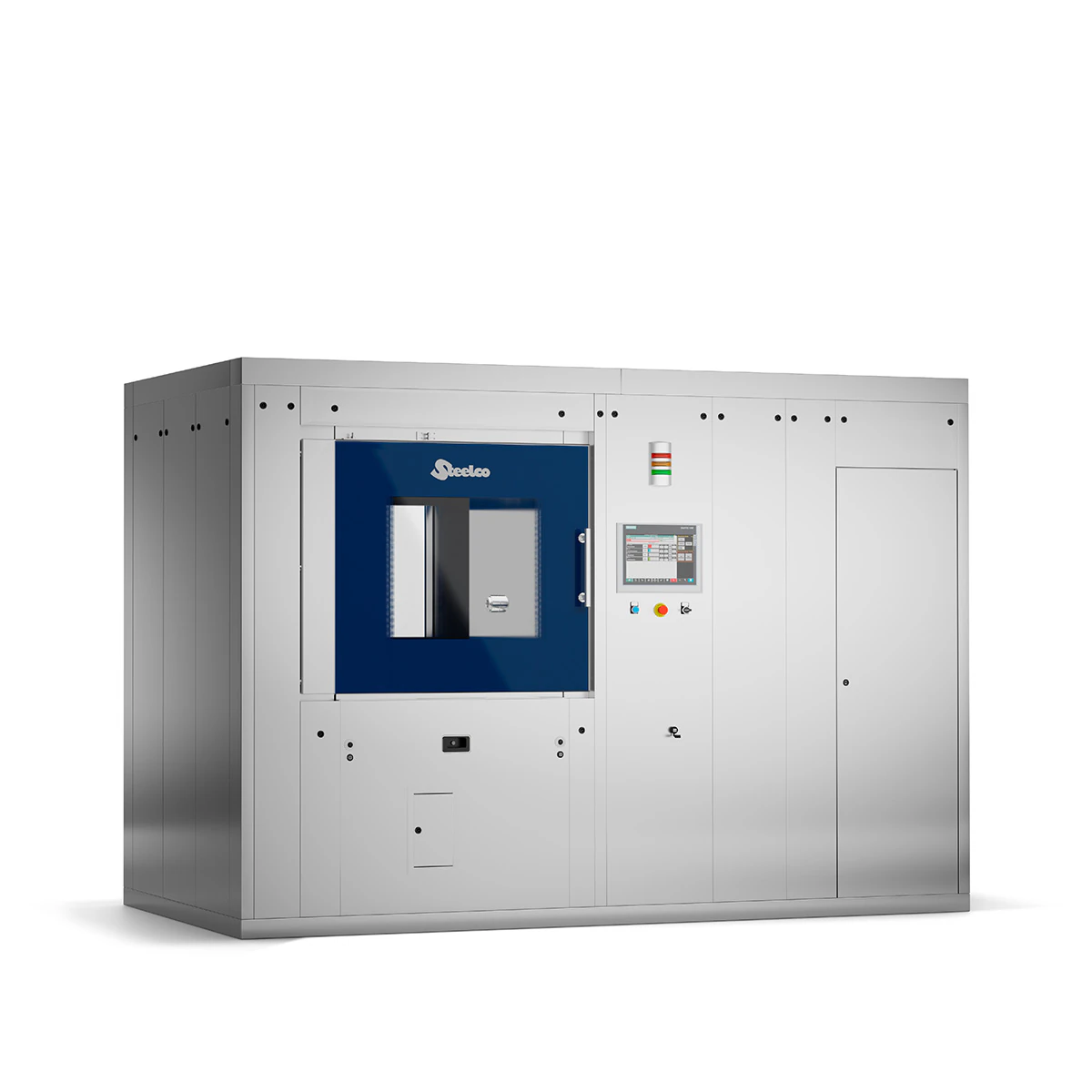

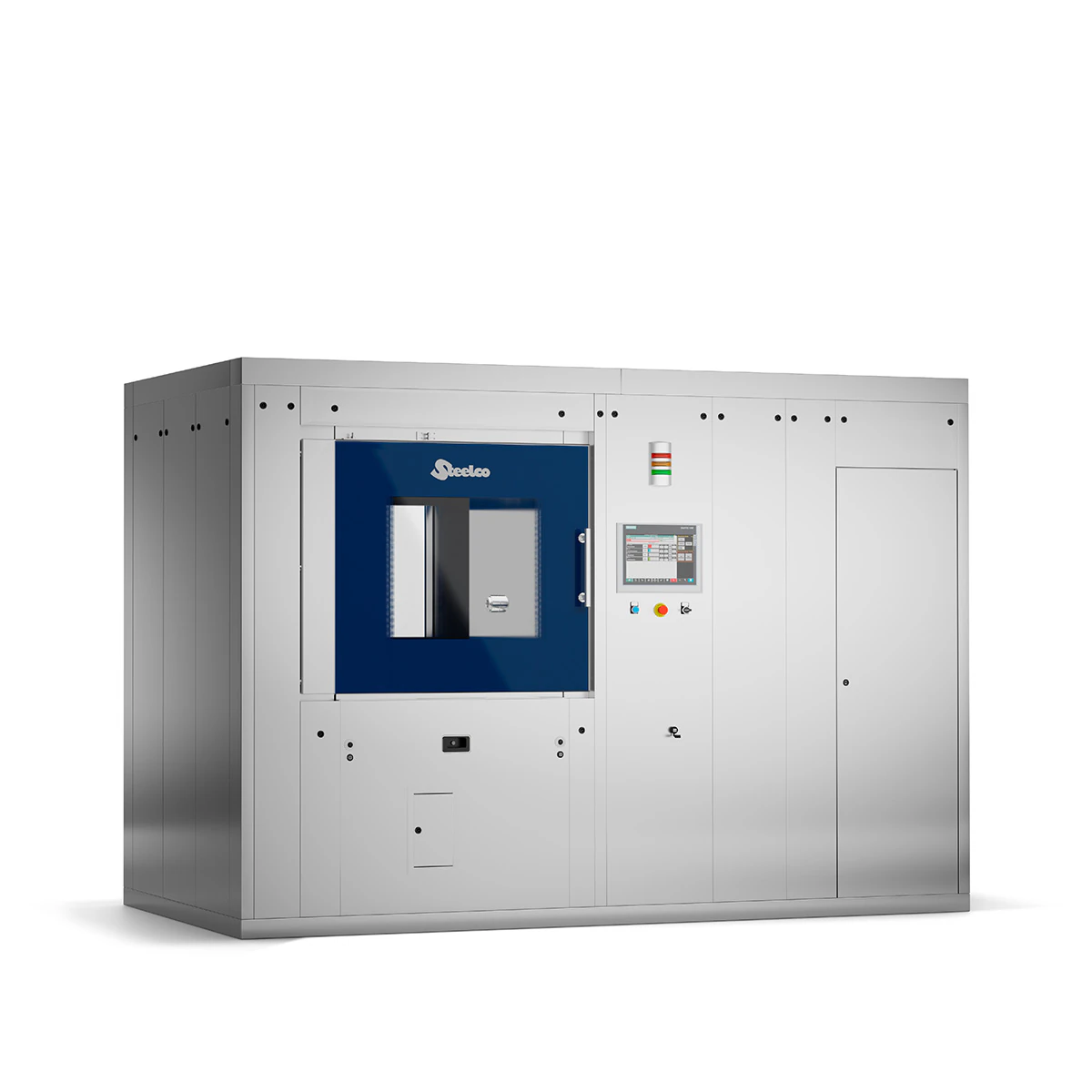

DS PH Series DS PH Series Pharma-Grade Part & Glassware Washers

High-Throughput, Validatable Cleaning Systems for Pharmaceutical and Biotech Environments

Key Features

-

Extensive Configuration Flexibility

Wide range of chamber sizes (230 to 2,400 litres) with over 400 configurable options to suit any production environment.

-

Fully GMP-Compliant Design

Chamber and piping self-clean during every cycle stage to eliminate cross-contamination risk.

-

Modular Installation

Technical area and cabinet placement options (left/right/remotely) allow flexible plant integration, even for inline machine setups.

-

User-Friendly Automation

Advanced 15″ HMI with Siemens or Allen-Bradley PLC, built to ISPE GAMP© and compliant with FDA 21 CFR Part 11 and EU Annex 11.

-

Remote Support Ready

Onboard VPN router enables secure remote diagnostics and assistance to reduce downtime and support costs.

Certifications

- cGMP-compliant | FDA 21 CFR Part 11 | EU Annex 11 | ISPE GAMP© V Guidelines | Material compliance to 21 CFR Part 177 (FDA-approved gaskets and seals)

Configurations

Chamber Volume (L) | Custom Sizes | Door Options | Heating Options | Surface Finish | Wetted Materials | Drying System | Enquire |

|---|---|---|---|---|---|---|---|

| 230 – 2400L | Available on request | Single or double door; vertical/horizontal sliding or hinged | Steam or Electrical heat exchanger | Ra<0.51 µm standard (Ra < 0.38 µm upon request) | AISI 316L stainless steel with FDA-approved gaskets | HEPA filtered; variable temperature; integrated or remote |

Thank you for requesting a quote. A member of our team will be in touch shortly.

Thank you for requesting a quote. A member of our team will be in touch shortly.